This Event was held at Serena hotel Nairobi on the 28th of June 2022 hosted by Gatsby Africa. Representatives from the forestry sector, furniture industry, and government institutions from Kenya and Uganda were in attendance. The event was organized into various sessions representing sections of the wood value chain from tree planting to all various end-use types as discussed below. Panelists from leading private firms in the businesses were chosen to highlight common problems, engage with participants and discuss solutions.

Commercial forestry sector

From the contributions submitted by representatives from Uganda Timber Growers Association (UTGA), it was evident that the commercial forestry in Uganda is more advanced than in Kenya. Under their Sawlog Production Grant Scheme (SPGS), the Uganda government in collaboration with the private sector managed to establish over 250,000 Ha of tree plantations. The UTGA continues to collaborate with other small scale tree farmers to increase this acreage. With low secondary processing capability in Uganda, UTGA was lobbying for market, investors, and partnerships for its timber resources. UTGA highlighted the challenge of taxes and unfavorable customs environment that hinders export into the Kenyan market. Other challenges include the lack of uniform regional timber grading standards and practice in quality assurance. UTGA gave a commitment to support and guide Kenya into commercial forestry by sharing their experience and management practices. Benefits of forest certification were also highlighted and FSC well represented.

Wood processing

From the discussion, there is a clear need to improve on the wood processing technology in Uganda and Kenya. Limited skilled labor in forestry operations such as logging to maximize output is needed on a regional scale. Here Mr Chris du Toit, a Timber Processing Specialist (TPS) emphasized the utilization of the whole tree, from bottom to leaves to maximize Return On Investment. In his presentation, he unveiled the KOMAZA processing plant that will be able to turn low quality grade timber into high end finished products. Other panelists included John Ferguson from Green Resources subsidiary called Busoga Forestry Company in Uganda. John Ferguson introduced his nzuri timber as a case study for packaging and branding. Busoga Forestry Company also produces kiln dried finger jointed timber of pine and eucalyptus.

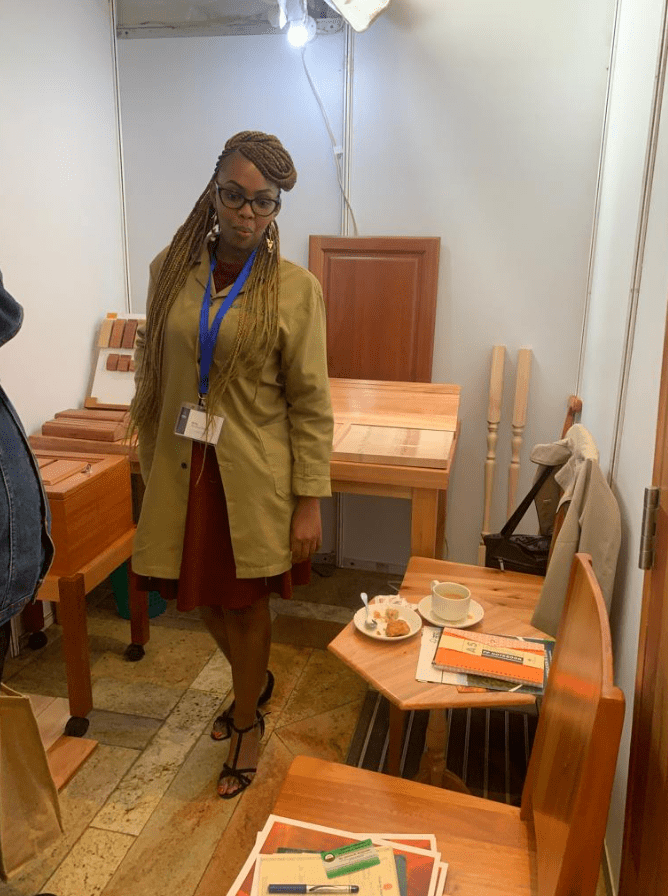

Furniture and Joinery firms

This was undoubtedly one of the most represented sectors in the event. This session started with a powerful presentation from Mr Hitesh Mediratta from the Kenya Association of Manufacturers (KAM). He gave an overview of the furniture and joinery sector in Kenya. Kenya has the highest taxes levied on finished furniture of (35%), making it the highest in the region. The country also has the highest cost of dried timber in the region driven by the low supply. The sector faces high competition from cheap imported furniture from China. Mr Hitesh also highlighted that this timber is made of various components that may not be necessary upto standards, that the KAM upholds. He emphasized that government intervention is urgently needed especially with the upcoming expansion of regional markets to African continental markets through removal of tariffs. However, market expansion could be an opportunity as well if the country capitalizes on its unique customized hand crafted furniture, added Mr. Naeem Biviji from Studio Propolis.

Manufacturers in the industry were also introduced to Human Centered Design (HCD) by Margin Innovation, in collaboration with the Gatsby Trust. HCD uses customer experiences, wants and needs to inform furniture designs, sales and marketing. This is aimed at maximizing resources to boost sales.

Use of eucalyptus in furniture manufacture was showcased and encouraged to preserve hardwoods from natural forests and reduce the cost of production.

Construction and building with sustainable wood

This sector was represented by contractors, engineers from building companies in Kenya, Kenya Green Building Society (KGBS), the Swedish Embassy in Nairobi, and Fairventures Worldwide. In order to establish timber construction in East Africa, timber needs to be presented as a sustainable building material that is not only flexible and affordable but can help Uganda and Kenya government meet their SDG targets. This was the emphasis of KGBS which put forward its objective and intent to lobby for wood as a construction company in Kenya. The Swiss embassy showcased various timber towers and shared their success story in shifting to green building. They also extended their interest in using this experience to help the region advance in construction with wood. BuildX Studio presented their ventures into Cross Laminated Timber (CLT), its benefits and challenges in promoting the engineered wood in Kenya. On the other hand, Fairventures Worldwide introduced the Glue Laminated Timber, and its potential benefits to timber value addition and use in structural applications. Despite these innovations, use of timber in construction in East Africa is very low. Challenges contributing to this trend were also highlighted. These included lack of standards and timber certification which limits use by engineers, lack of skilled labor to design and build with timber, commitment from governments to recognise timber as a capable alternative construction material among others. In order to improve the overall use of wood in construction, it is important to start with small fittings and maximize all parts of the building where wood is used such as floors, joinery, doors, frames, furniture, roof trusses among others.

There were concerns about wood preservation, fire protection and durability. Besides highlighting roof trusses as one of the traditional applications of wood that is not treated or protected from fire, prototyping was suggested to demonstrate what timber can do.

The day was closed by a discussion merging all sessions and segments in the timber value chain. At the end, it was evident that the success of the Forestry sector in the region depends on collaboration of industry players along the entire value chain with regulators (governments).

Written by Juliet Nanyonga & Simon Bosch